3D printed blue light

Scheurer Swiss uses 3D printing to produce blue light dummies for the conversion of a former Swiss fire engine into a true-to-the-original event vehicle.

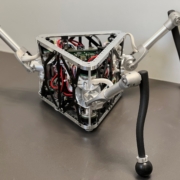

Scheurer Swiss GmbH, a specialist in the field of product development with state-of-the-art fibre composite and lightweight construction technologies, was recently commissioned with the additive manufacturing of three blue light dummies for the conversion of a fire engine once used as a company fire brigade vehicle produced by the well-known Swiss motor vehicle manufacturer “General Dynamics European Land Systems – Mowag GmbH” into an original vintage event bus. The blue light fairings, made of highly UV light and weather resistant plastic, serve as a replacement for the originally functional blue lights of the original Swiss fire engine built in 1987, as their operation, within the framework of the civil use of the vehicle, is not permitted.

From fire engine to vintage car thanks to additive manufacturing

In the modern lightweight construction technology also known as 3D printing, a digital model is transformed into a physical, three-dimensional component by adding material layer by layer. A special feature of additive manufacturing is that the objects are produced without tools and without complex moulds, directly on the basis of 3D computer data, so-called rapid product development. Compared to conventional manufacturing processes, this increases flexibility – in particular, components with a high degree of customisation can be produced promptly and cost-efficiently with the necessary stability and functionality.

3D printing allows the flexible and fast production of stable, resistant and cost-efficient components and one-offs based on a computer model.

“We deliberately chose 3D printing for the production of the fire brigade blue light dummies. It allows us to produce a wide variety of stable and resistant components and unique items like these, based on a computer model, flexibly, quickly and with the lowest possible material consumption in a cost-efficient manner. “, says lightweight construction expert and owner of Scheurer Swiss, Dominik Scheurer, and continues: “Sometimes, as in this case, even a simple hand sketch from the customer is sufficient as input for the subsequent computer-aided 3D design of the customised components. ”

Plastics as a material for 3D printing

On one and the same 3D printer, different additive manufacturing processes can be used to process different materials, for example nylon or carbon reinforced plastics. In the case of the blue light cladding of the original Mowag fire truck, which was to be converted into an event bus, Scheurer opted for the highly weather-resistant ASA plastic. The engineer emphasises: “Due to its high UV and weather resistance, this plastic is ideally suited for end products that are used outdoors. ”

The 3D-printed blue light dummies, made from UV- and weather-resistant ASA plastic, were further processed using the classic painting process.

3D-printed components made of these and other, also fibre-reinforced materials, can also be excellently processed. For example, the new blue lights of the Mowag B300 were further processed after printing at a body shop using the classic painting process. First the covers were filled, then painted with water-based paint. The filler smoothes out any unevenness and also serves as corrosion protection. It also provides optimal adhesion for the subsequent paint coat. “In this case, our customer opted for a paint finish in ultramarine blue to come as close as possible to the original blue lights,” Scheurer shares.

3D printing: the future of production technology

The lightweight construction expert is certain: “Additive manufacturing is currently one of the most modern lightweight construction technologies and is shaping the future of the manufacturing industry like hardly any other process. The intention is clear: even more flexibility, creativity and cost efficiency in product development. ”

Thanks to its roots in Formula 1 motorsport, Scheurer Swiss has over thirty years of experience in the field of lightweight construction and is the only provider in Switzerland to offer a complete service: from consulting, design and engineering to production – all from a single source. We are happy to advise you!

Scheurer Swiss GmbH

Scheurer Swiss GmbH Scheurer Swiss-Toyota Gazoo Racing

Scheurer Swiss-Toyota Gazoo Racing Scheurer Swiss-Aartesys

Scheurer Swiss-Aartesys Scheurer Swiss GmbH-ETH Zürich

Scheurer Swiss GmbH-ETH Zürich Scheurer Swiss-Black Star Sailing

Scheurer Swiss-Black Star Sailing Scheurer Swiss-Moonwave Gunboat

Scheurer Swiss-Moonwave Gunboat Scheurer Swiss - ETH Zürich

Scheurer Swiss - ETH Zürich

Scheurer Swiss-ETH Zurich

Scheurer Swiss-ETH Zurich Scheurer Swiss-Aartesys

Scheurer Swiss-Aartesys