The goal of every product development team and designer is to create the perfect item that works well, solves a problem for the customer and ideally reduces costs. 3D printing is already recognized as a manufacturing process that can achieve these goals. It offers the designer freedom of design and new possibilities in product development or optimization. Even if the designers are the best in their field and very familiar with the CAD software, there are still some optimization opportunities that the human eye can miss. This is where topology optimization comes into play. But what is it and how does this process work?

Simply put, Topology Optimization (TO) is a process that optimizes a part by reducing unnecessary material. It involves improving the geometry of a part using mathematics to find out where an object needs material and where the material has no benefit in the efficiency and performance of the eventual product and is only there for aesthetic reasons. The aim of the TO is to create an object with the best possible performance, saving as much material as possible.

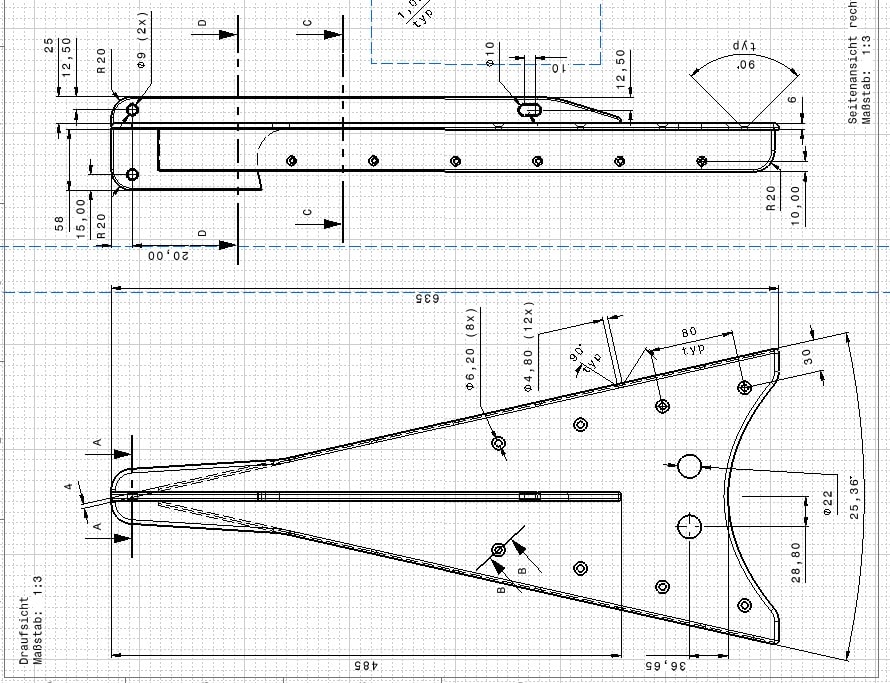

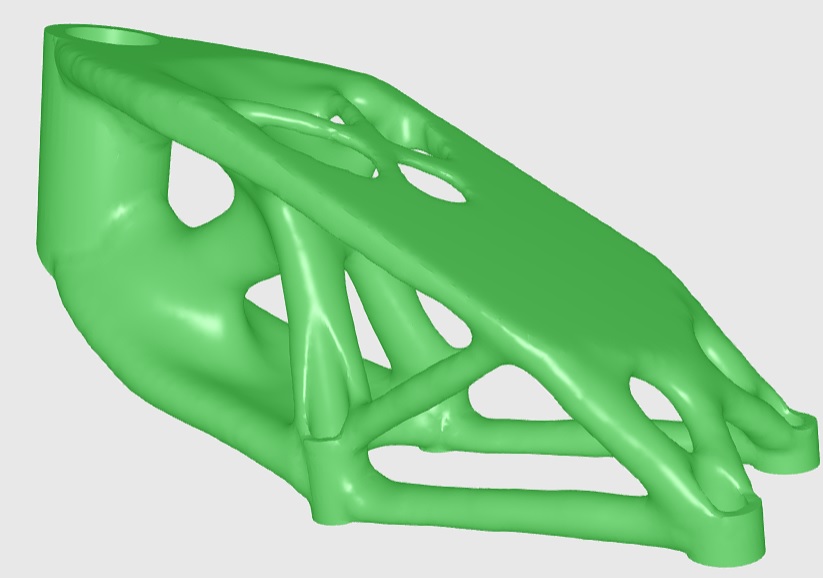

CAD Imput File

Topology optimization is often associated with additive manufacturing because optimized parts can be easily produced with 3D printing. 3D printing or additive manufacturing is a growing manufacturing technique, whether for prototypes or end products. It gives the designer the freedom to design the part, save it to a 3D file, and then send it to print. The printer creates the object layer by layer. This gives companies the opportunity to transform a digital object into a physical form. There are different types of printers and materials that can be used. Selective laser sintering is best suited for printing plastics. DMLS or binder jetting technology should be used for metal parts.

Traditional manufacturing processes can also work with TO models, but typically they have higher limits and cannot take the next step in topology optimization. The freedom of design offered by Additive Manufacturing is the complementary process to take full advantage of TO.

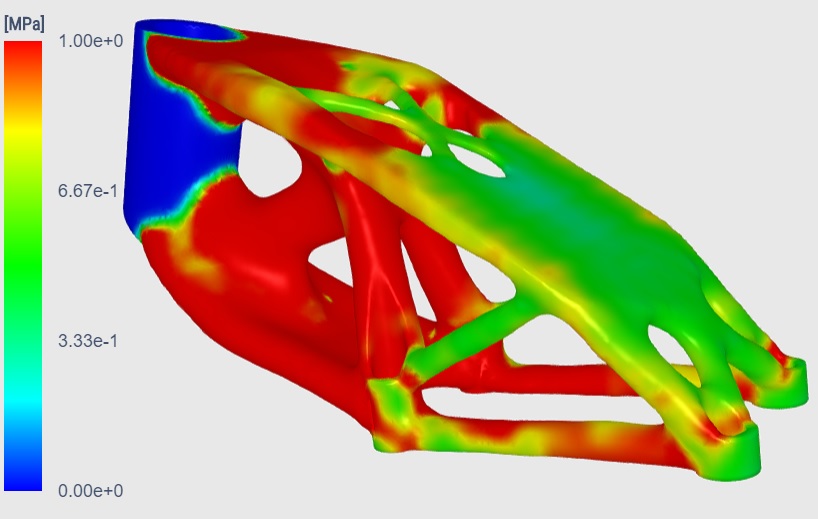

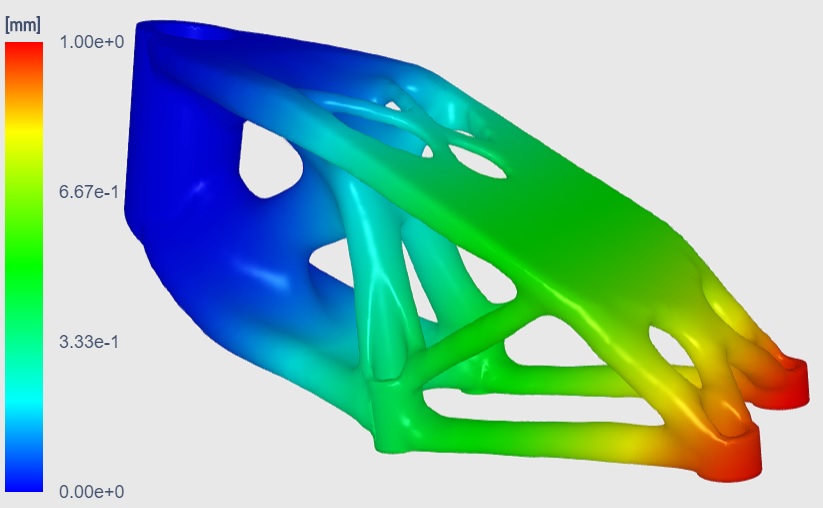

Stress Analysis

TO is becoming more and more common as many industries such as aerospace, biochemistry, construction, medical or automotive use it to produce strong parts with less material usage. In their use case, Altair showed how topology optimization saves 500 kg on an aircraft. This weight loss automatically means lower fuel consumption, since the heavier the aircraft, the more fuel it needs.

Process of a topology optimization

Although there are different TO methods, the most common is the FE (Finite Element) based technique.

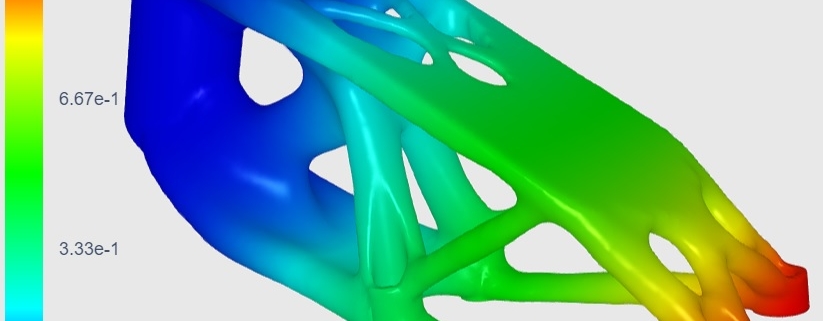

First, the user must define the part of the object that includes the maximum volume that the object can occupy. This is also called “design space”. Then the user specifies the external forces under which the object is to be tested. This is the tricky part of optimization because it is important to know exactly what external forces are acting on the part. It is not enough to know the forces. It is important to know how big the forces are and how to define them. When the adjustments are added, the TO algorithm in the following simulation finds places that can be removed while the object still withstands the external stresses.

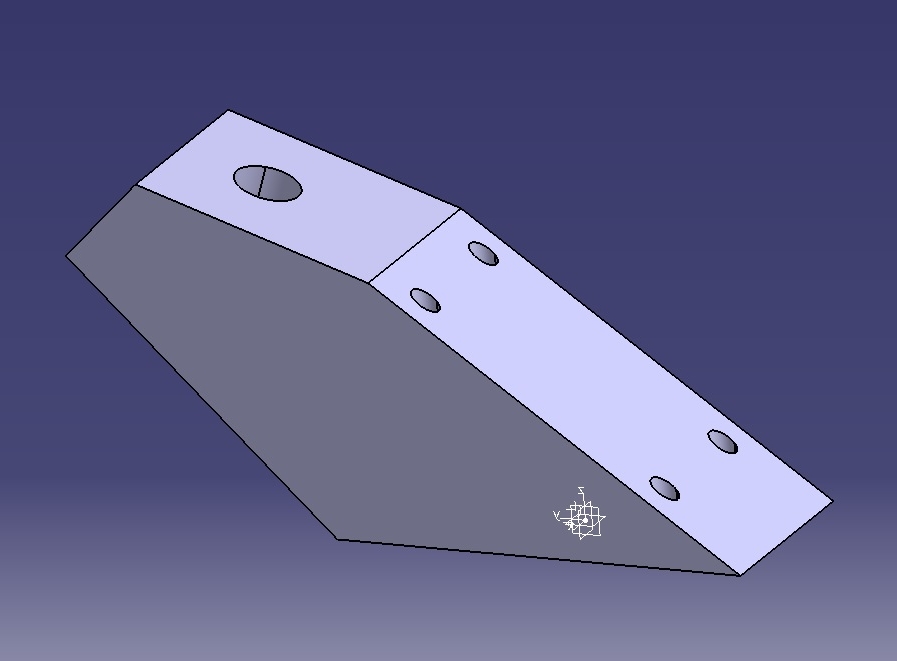

The software then suggests different design ideas by reducing the material used. Each time a part of the material is removed, the algorithm checks whether the object would still function under the set load. After the user is satisfied with the result of the simulation, the object is checked for printability. Sometimes the user tweaks the design again to make the object look more aesthetic than the result of the simulation.

Displacement Analysis

Topology Optimization vs. Generative Design

Topology optimization is often described as a form of generative design. But what exactly are the differences between these two methods? Generative design creates multiple possible designs, which is helpful when the designer is unsure of what type of shape or design is needed. TO focuses on just one design and all the ways to optimize it. For example, if a shape is selected from the Generative Design selection, TO can be used to optimize the shape. This means TO is used by Generative Design. However, TO never uses generative design for proposals because it needs a single design input to work with.

Output CAD File

What is the benefit of TO?

• Shortening of the design process

Topology optimization helps create the final design faster, which means the overall time-to-market process is reduced. The algorithm works faster and more effectively than human work could. This means time can be saved in the design process as fewer iterations are required to arrive at a final design.

• Less material for lighter parts

Another positive aspect is that a topologically optimized part requires less material in production. 3D printing helps reduce the amount of wasted material, as only the material needed is used in manufacturing. The optimized models require even less material. This saves costs and makes the part lighter. The optimized product contributes to more sustainability because the material is not processed unnecessarily.

• Cost savings

You can of course save money with topology-optimized parts, but how? Reduced time to market means less money is put into the development process. Another aspect is production, since less material is needed to produce the part. As already mentioned, industries like automotive or aerospace use TO for their products.

• Better part performance

By omitting unnecessary material, TO also helps designers design a product that will generally perform better as the simulation tests it according to the designer’s settings. This is a way of predicting stress and ensuring that the part is designed to withstand external forces.

More information or free advice for your project/component? We look forward to hearing from you.

Scheurer Swiss-Blink

Scheurer Swiss-Blink