ETH focus project «Rowesys»

Scheurer Swiss supports the focus project “Rowesys” – Robotic Weeding System – of ETH Zurich with its engineering know-how and supplies 3D-printed carbon-reinforced robot components.

The engineering company Scheurer Swiss GmbH, known for its many years of expertise with fibre composite technologies, is supporting the “Rowesys” – Robotic Weeding System – project of ETH Zurich as a gold sponsor with its engineering expertise and is printing carbon-reinforced 3D components for the agricultural robot on behalf of the team. With this concept, ten motivated ETH students are pursuing the goal of developing a sustainable alternative for the use of herbicides in agriculture. Their autonomous agricultural robot for weed removal has just gone into practical testing.

Carbon-reinforced material revolutionizes agriculture

“Rosie”, the unprecedented autonomous agricultural robot, was developed by ETH students in collaboration with Scheurer Swiss as a gold sponsor and is expected to replace pesticides in the future.

The ETH Zurich focus project “Rowesys”, supported by Scheurer Swiss, impressively demonstrates how damage to people and the environment can be minimised with the help of digitalisation and smart technology. With this goal in mind, ten motivated ETH students, supported by eight expert coaches and sponsors, have been working on the development of the “Rowesys” agricultural robot since last September.

The underlying concept is based on mechanical weed killing. The result is a functional prototype for sugar beet fields, because these require a relatively high use of herbicides. “Rowesys” already meets the requirements of an autonomous agricultural robot in terms of efficiency, reliability, autonomy, safety and user-friendliness to a large extent. Not least thanks to the use of cost-efficient carbon-reinforced material from the 3D printer, which, in addition to the monetary benefits, also offers practically unlimited design possibilities.

For example, the agricultural robot has been equipped with wafer-thin carbon-reinforced plastic slats that are backed by LEDs to indicate the robot status at all times.

Wafer-thin carbon-reinforced plastic slats from the 3D printer of Scheurer Swiss GmbH.

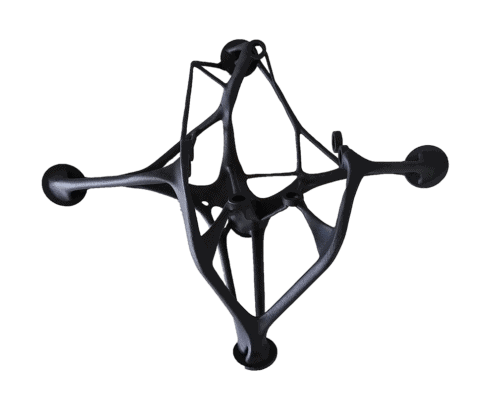

Another filigree component in turn serves as an interface between the aluminium chassis and the robot’s electronics. The unusual shape of the connector is designed in such a way that not a single gram of superfluous material is used, so as not to weigh down the robot unnecessarily. At the same time, the component must be ultra-stable to hold the connection.

Carbon-reinforced connecting piece between the case and electronics, printed in 3D by Scheurer Swiss.

“Only with the technology of carbon-reinforced 3D printing is it even possible to produce such a precisely fitting, filigree and yet stable component.

The carbon reinforced 3D printing technology recommended by Scheurer Swiss is the perfect solution in terms of lightweight construction, design flexibility and stability as well as manufacturing time and production costs.

We supported the Rowesys team with our know-how in the field of fibre composite technologies in an advisory capacity and operationally incorporated our many years of expertise from the development of highly efficient composite components for motor sports into the development and 3D printing of the carbon-reinforced components for the agricultural robot,” explains Dominik Scheurer, CEO of Scheurer Swiss GmbH.

The agricultural robot is to replace pesticides

The agricultural robot pulls small ploughs through the soil, which destroy the weeds between the rows of plants by pulling the roots to the surface from the ground where the weeds dry up. The robot drives autonomously through the rows, detects the end of the field with the help of the built-in cameras and switches to the next untilled row. This process is repeated until the end of the field is reached.

The “Rowesys” project at ETH Zurich, which is supported by Scheurer Swiss, impressively demonstrates how damage to people and the environment can be minimized with the help of digitalization and smart technology.

The practical test has shown that with “Rowesys” both the use of herbicides and the pollution of groundwater, air and produced goods can be massively reduced. “What motivated me about this project, apart from the relevance of what I learned and the chance to gain practical experience in teamwork, was the sustainability of herbicide-free sugar beet cultivation. Because up to now, there has been no investment in more sustainable production in this area of agriculture,” says Nico Burger, Software & Controls Team Rowesys.

“The focus project “Rowesys” is an example of how digitisation and the use of innovative materials can produce efficient and intelligent technical achievements. We congratulate the Rowesys team on their success and are pleased that we were able to support the team with our expertise in an advisory and operational capacity right up to the practical test”, Scheurer announced.

Your project in good hands

Scheurer Swiss GmbH is the only provider in Switzerland that offers the complete process from consulting to engineering and production within its service portfolio in the field of lightweight composite engineering. In addition, Scheurer Swiss GmbH provides high performance composite know-how in the context of professional and licensed personnel placement as well as customer-specific composite training on a long-term basis. We will be happy to advise you!

Scheurer Swiss GmbH-ETH Zürich

Scheurer Swiss GmbH-ETH Zürich Scheurer Swiss-Moonwave Gunboat

Scheurer Swiss-Moonwave Gunboat

Scheurer Swiss-Blink

Scheurer Swiss-Blink Scheurer Swiss-Aartesys

Scheurer Swiss-Aartesys Scheurer Swiss-Toyota Gazoo Racing

Scheurer Swiss-Toyota Gazoo Racing Scheurer Swiss-Black Star Sailing

Scheurer Swiss-Black Star Sailing

Scheurer Swiss GmbH

Scheurer Swiss GmbH Scheurer Swiss-ETH Zurich

Scheurer Swiss-ETH Zurich