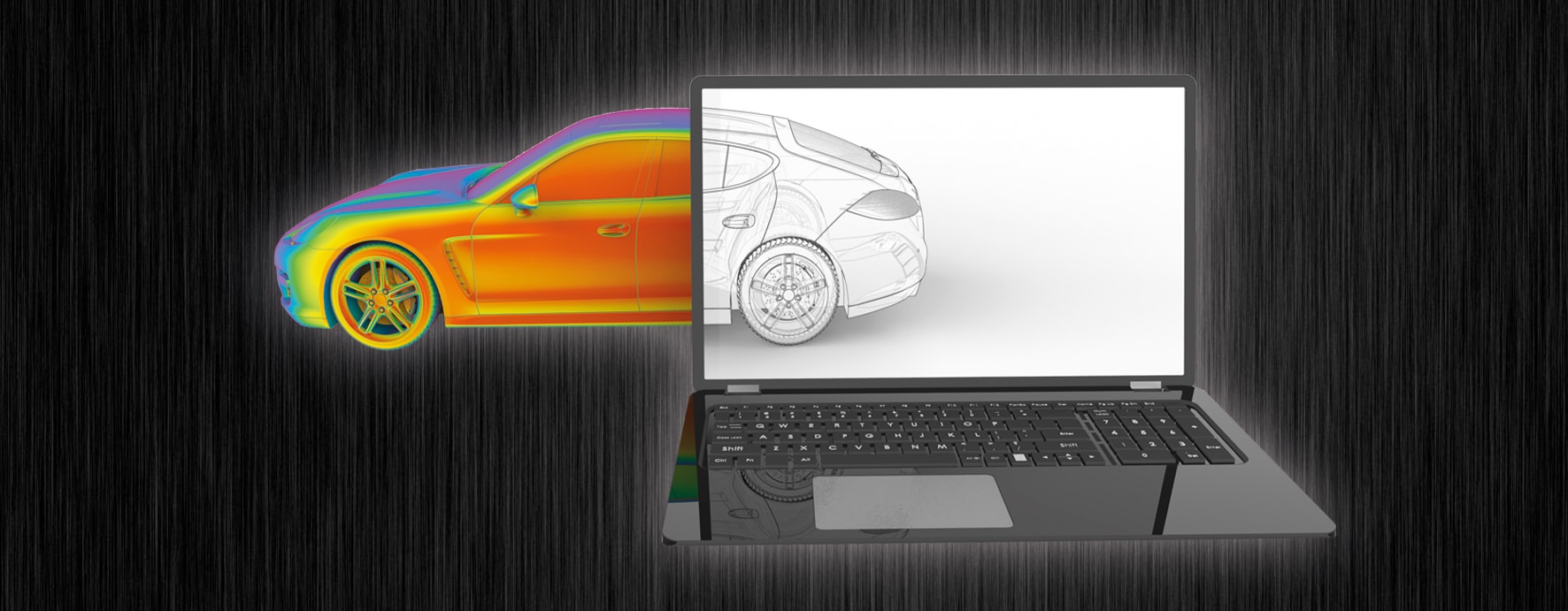

Das Ziel jedes Produktentwicklungsteams und jedes Konstrukteurs ist es, den perfekten Artikel zu schaffen, der gut funktioniert, ein Problem für den Kunden löst und im Idealfall Kosten senkt. Der 3D-Druck wird bereits als ein Fertigungsverfahren angesehen, mit dem diese Ziele erreicht werden können. Er bietet dem Designer Gestaltungsfreiheit und neue Möglichkeiten bei der Produktentwicklung oder -optimierung. Auch wenn die Konstrukteure die Besten auf ihrem Gebiet sind und sich mit der CAD-Software bestens auskennen, gibt es doch einige Optimierungsmöglichkeiten, die das menschliche Auge übersehen kann. An dieser Stelle kommt die Topologieoptimierung ins Spiel. Aber was ist das, und wie funktioniert dieser Prozess?

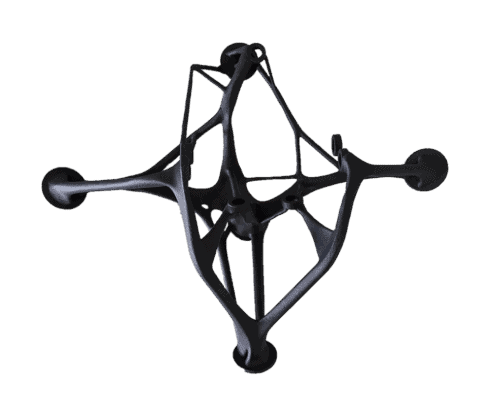

Einfach ausgedrückt, ist die Topologie Optimierung (TO) ein Prozess, der ein Teil durch die Reduzierung von unnötigem Material optimiert. Dabei wird die Geometrie eines Teils mit Hilfe der Mathematik verbessert, um herauszufinden, wo ein Objekt Material benötigt und wo das Material keinen Nutzen für die Effizienz und Leistung des späteren Produkts hat und lediglich aus ästhetischen Gründen vorhanden ist. Das Ziel der TO ist es, ein Objekt mit der bestmöglichen Leistung zu schaffen, wobei so viel Material wie möglich eingespart wird.

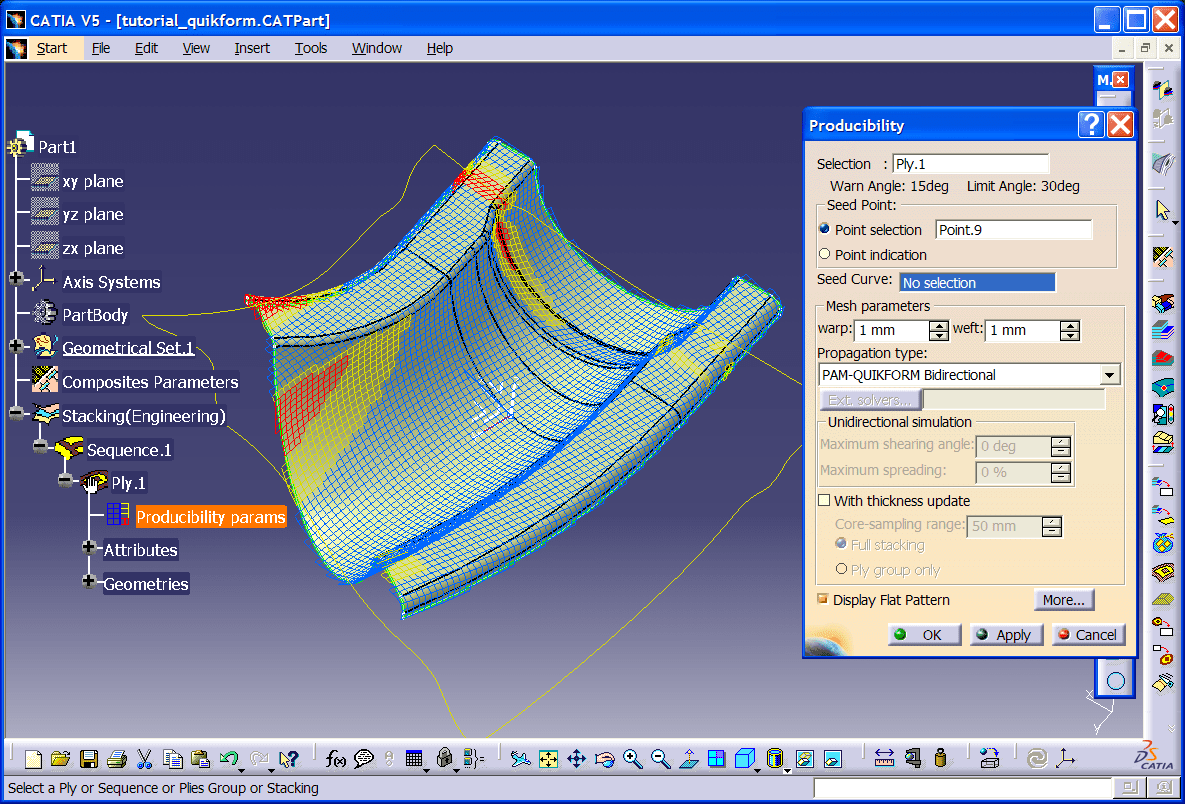

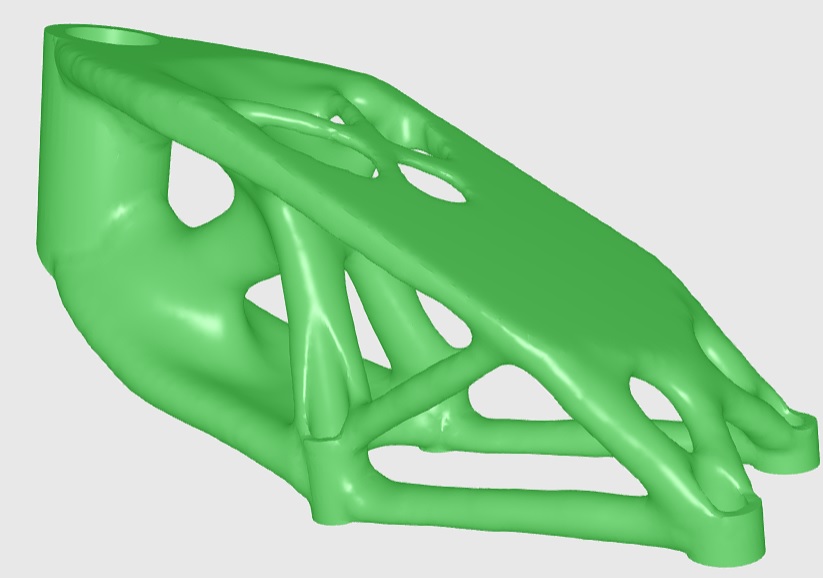

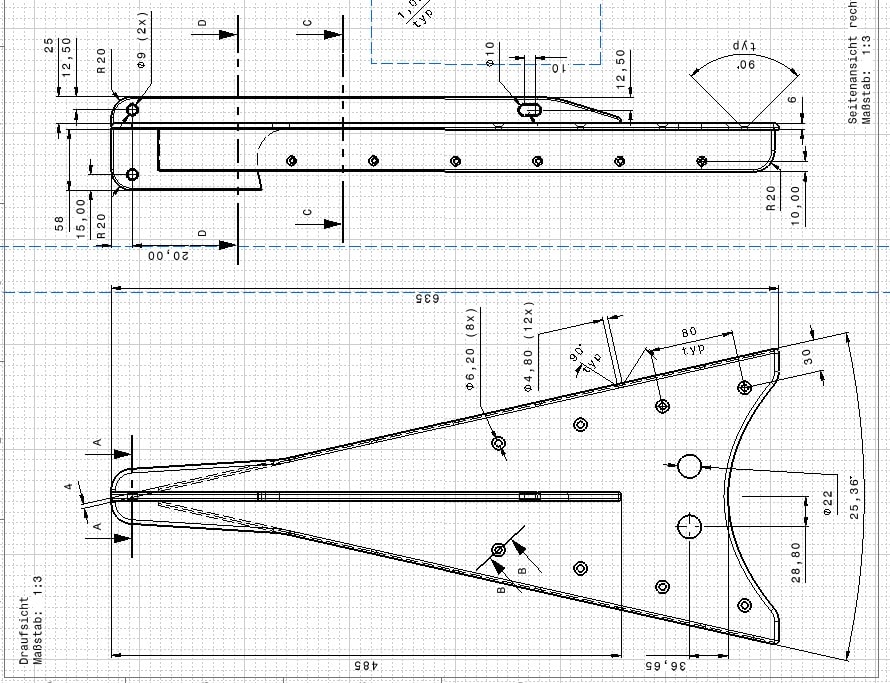

CAD-Imput Datei

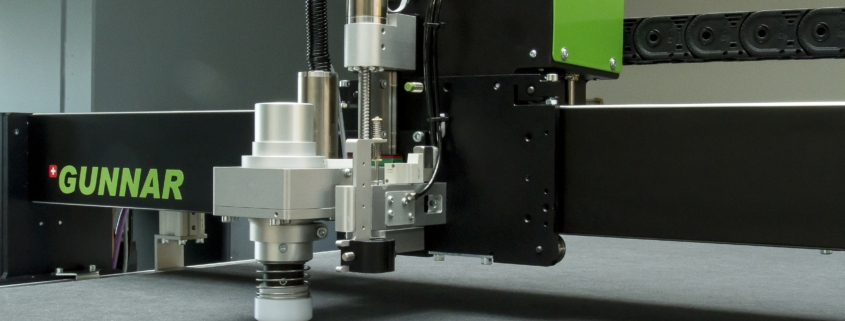

Die Topologieoptimierung wird oft mit der additiven Fertigung in Verbindung gebracht, da sich optimierte Teile leicht mit dem 3D-Druck herstellen lassen. 3D-Druck oder Additive Manufacturing ist eine wachsende Fertigungstechnik, ob für Prototypen oder Endprodukte. Es gibt dem Designer die Freiheit, das Teil zu entwerfen, es in einer 3D-Datei zu speichern und dann zum Druck zu schicken. Der Drucker erstellt das Objekt Schicht für Schicht. Unternehmen haben so die Möglichkeit, ein digitales Objekt in eine physische Form zu verwandeln. Es gibt verschiedene Arten von Druckern und Materialien, die verwendet werden können. Für den Druck von Kunststoffen eignet sich am besten das selektive Lasersintern. Für Metallteile sollte die DMLS– oder Binder-Jetting-Technologie verwendet werden.

Auch herkömmliche Fertigungsverfahren können mit TO-Modellen arbeiten, aber in der Regel haben sie höhere Grenzen und können bei der Topologieoptimierung nicht den nächsten Schritt machen. Die Freiheit des Designs, welche die Additive Fertigung bietet, ist das ergänzende Verfahren, um alle Vorteile von TO zu nutzen.

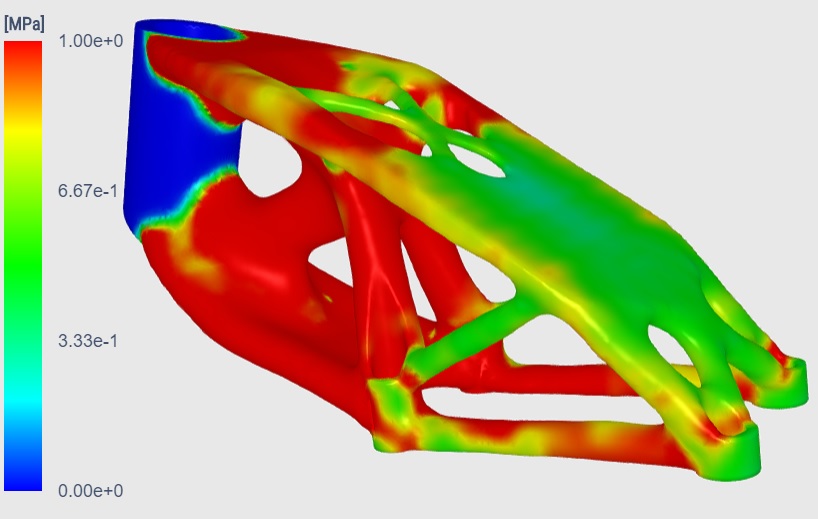

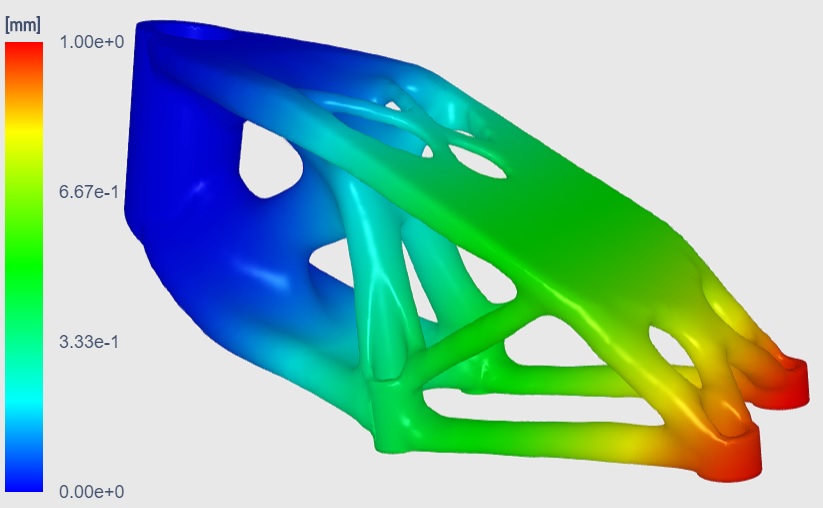

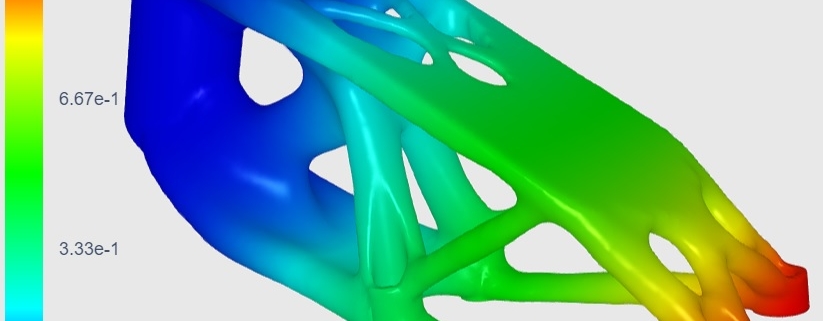

FEM Belastungsanalyse

TO wird immer häufiger eingesetzt, da viele Industriezweige wie Luft- und Raumfahrt, Biochemie, Bauwesen, Medizintechnik oder Automobilbau damit arbeiten, um starke Teile trotz geringerem Materialeinsatz herzustellen. In ihrem Anwendungsfall zeigte Altair, wie Topologieoptimierung 500 kg bei einem Flugzeug einspart. Dieser Gewichtsverlust bedeutet automatisch einen geringeren Verbrauch, denn je höher das Gewicht eines Flugzeugs ist, desto mehr Treibstoff wird benötigt.

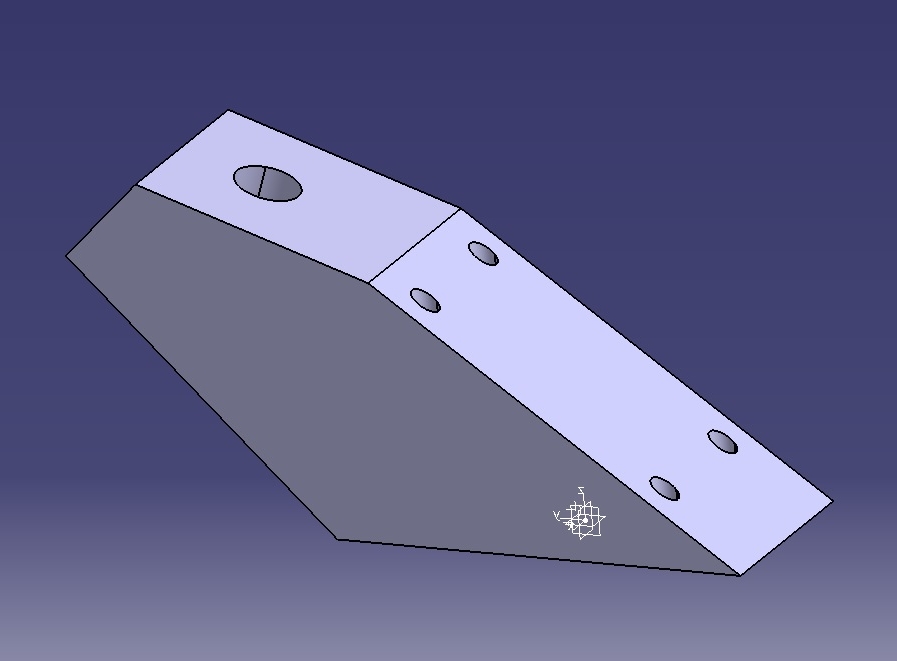

FEM Verschiebungsanalyse

Ablauf einer Topologieoptimierung

Obwohl es verschiedene TO-Methoden gibt, ist die am weitesten verbreitete die FE (Finite Elemente)-basierte Technik.

Zunächst muss der Benutzer den Teil des Objekts definieren, der das maximale Volumen umfasst, welches das Objekt einnehmen kann. Dies wird auch “Designraum” genannt. Dann legt der Benutzer die äußeren Kräfte fest, unter denen das Objekt getestet werden soll. Dies ist der schwierige Teil der Optimierung, denn es ist wichtig, genau zu wissen, welche äußeren Kräfte auf das Teil einwirken. Es reicht nicht aus, die Kräfte zu kennen. Wichtig ist, dass man weiß, wie groß die Kräfte sind und wie man sie definieren kann. Wenn die Einstellungen hinzugefügt werden, findet der TO-Algorithmus in der folgenden Simulation Stellen, die entfernt werden können während das Objekt trotzdem den äußeren Belastungen standhält.

Die Software schlägt dann verschiedene Designideen vor, indem sie das verwendete Material reduziert. Jedes Mal, wenn ein Teil des Materials entfernt wird, prüft der Algorithmus, ob das Objekt unter der eingestellten Belastung noch funktionieren würde. Nachdem der Benutzer mit dem Ergebnis der Simulation zufrieden ist, wird das Objekt auf Druckbarkeit geprüft. Manchmal passt der Benutzer das Design noch einmal an, damit das Objekt ästhetischer aussieht als das Ergebnis der Simulation.

Topologieoptimierung vs. generatives Design

Die Topologieoptimierung wird oft als eine Form des generativen Designs beschrieben. Aber wo genau liegen die Unterschiede zwischen diesen beiden Methoden? Generatives Design erzeugt mehrere mögliche Designs, was hilfreich ist, wenn der Designer nicht sicher ist, welche Art von Form oder Design benötigt wird. TO konzentriert sich nur auf ein einziges Design und alle Möglichkeiten, dieses zu optimieren. Wenn zum Beispiel eine Form aus der Auswahl des Generativen Designs ausgewählt wird, kann TO zur Optimierung der Form verwendet werden. Das bedeutet, dass TO von Generativen Entwürfen verwendet wird. TO verwendet jedoch niemals generatives Design für Vorschläge, da es eine einzige Entwurfseingabe benötigt, mit der es arbeiten kann.

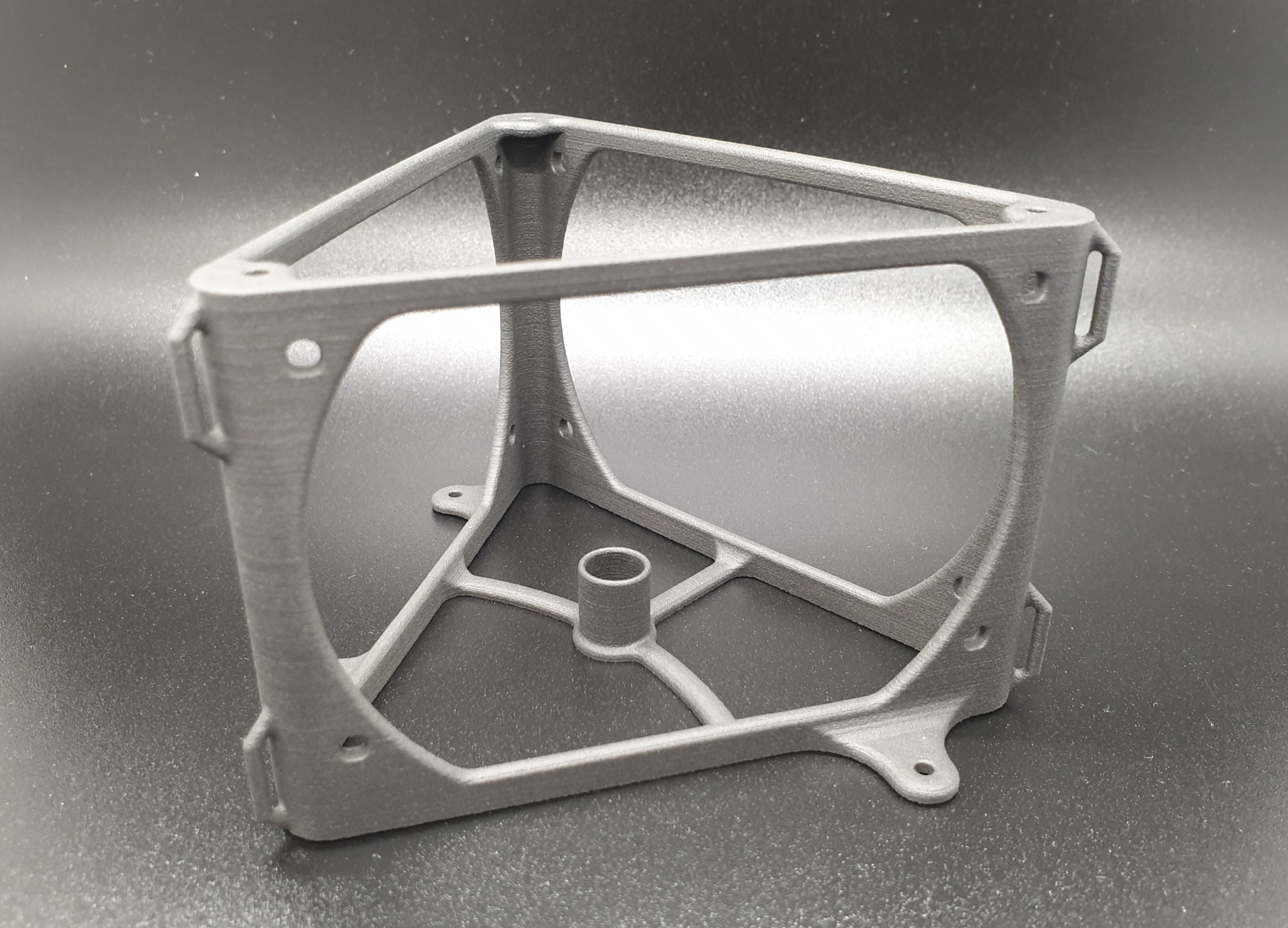

Output CAD Datei

Welchen Vorteil hat TO?

· Verkürzung des Designprozesses

Die Topologieoptimierung trägt dazu bei, das endgültige Design schneller zu erstellen, was bedeutet, dass sich der allgemeine Time-to-Market-Prozess verkürzt. Der Algorithmus arbeitet schneller und effektiver als es menschliche Arbeit könnte. Das bedeutet, dass im Designprozess Zeit eingespart werden kann, da weniger Iterationen erforderlich sind, um zu einem endgültigen Design zu gelangen.

· Weniger Material für leichtere Teile

Ein weiterer positiver Aspekt ist, dass ein topologisch optimiertes Teil in der Produktion weniger Material benötigt. Der 3D-Druck trägt dazu bei, die Menge an verschwendetem Material zu reduzieren, da nur das benötigte Material für die Herstellung verwendet wird. Bei den optimierten Modellen wird sogar noch weniger Material benötigt. Das spart Kosten und macht das Teil leichter. Das optimierte Produkt trägt zu mehr Nachhaltigkeit bei, da das Material nicht unnötig verarbeitet wird.

· Kostenersparnis

Mit Topologie-optimierten Teilen können Sie natürlich Kosten einsparen, aber wie? Durch die verkürzte Zeit bis zur Markteinführung wird weniger Geld in den Entwicklungsprozess gesteckt. Ein weiterer Aspekt liegt in der Produktion, da weniger Material für die Herstellung des Teils benötigt wird. Wie bereits erwähnt, verwenden Branchen wie die Automobilindustrie oder die Luft- und Raumfahrt TO für ihre Produkte.

· Bessere Leistung der Teile

Durch das Weglassen von unnötigem Material hilft TO den Konstrukteuren auch dabei, ein Produkt zu entwerfen, das im Allgemeinen leistungsfähiger ist, da die Simulation es entsprechend den Einstellungen des Konstrukteurs testet. Auf diese Weise kann die Beanspruchung vorhergesehen und sichergestellt werden, dass das Teil so gestaltet ist, dass es den äußeren Kräften standhält.

Weitere Informationen oder eine kostenlose Beratung für Ihr Projekt/Bauteil? Wir freuen uns auf die Kontaktaufnahme.

Scheurer Swiss-Blink

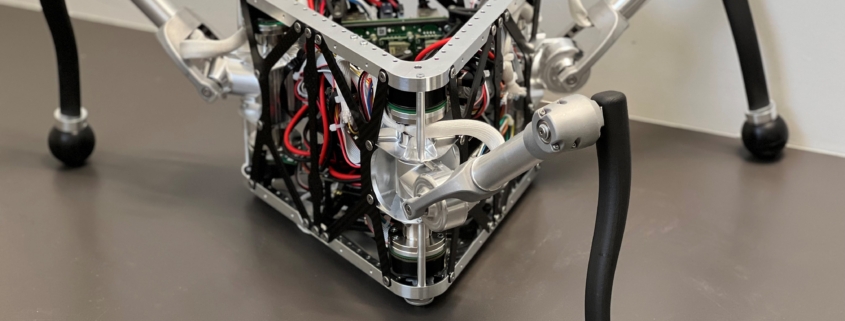

Scheurer Swiss-Blink

Scheurer Swiss - ETH Zürich

Scheurer Swiss - ETH Zürich

Scheurer Swiss-Aartesys

Scheurer Swiss-Aartesys